Find out why and how presidents of MOBIO exhibitors started "INNOVATION and CHALLENGE" through the special interview. The latest "Meet the President" article is Mr. Kodan of KODAN METAL CO., LTD.

- Sintered metal parts

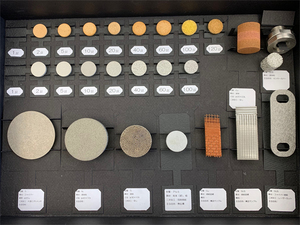

●Succeeded in developing a variety of sintered metal that was only bronze and stainless steel

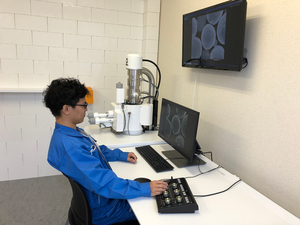

Until 2013, KODAN had commercialized sintered metal of two types, bronze and stainless steel. Mr. Kodan took on the big challenge of introducing a sintering machine (electric furnace) for the development of new materials, despite the slugish sales. As a result, KODAN has succeeded in developing 12 or more new materials that are second to none in the industry. In recognition of its technological efforts and efforts toward corporate growth, KODAN acquired "ISO9001" and also received an "Excellent Company of OSAKA" certificated by Osaka Prefectural Government in 2014.

●The unyielding challenge spirit that makes even impossible possible bears fruit.

Sintered metal is made of the granular metal that is heated to a temperature below the melting point to form an aggregate. When trying to create a completely new sintered metal material from the scratch, there were many difficulties. Kodan could obtain a material that met the conditions such as grain shape, size, lot number, and cost. However a material is available, expertise of sintering varies a lot depending on the material.

Repeating a lot of tryes and errors, in some cases, the materials that are theoretically written as "impossible" in the literature have been successfully sintered. "The joy of succeeding in development is hard to replace," says Kodan.

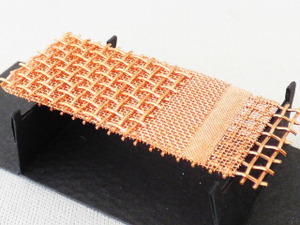

The company mainly deals with sintered metal, which is a porous sintered body that makes use of the gaps between grains and a thin sintered wire mesh (laminated wire mesh) that controls the filtration holes by stacking wire mesh. In the past, it was often used for purposes such as filtering, explosion proofing, and noise reduction. As the number of materials increases, the range of uses also expands, creating needs that even the company did not expect.

Kodan said, "Even if it doesn't result in expected shape, the ideas and experiences gained in the process will be used somewhere later. There will always be a time when it will sell. And it's more interesting to think about how KODAN can develop something that has never existed before, rather than something that anybody can produce by using a machine". And he said, "The more difficult the request, the more motivated".

--

Interviewed on January 14, 2020

Send your question or request from here to KODAN METAL CO., LTD.