There is a Special Exhibit at MOBIO Tech Hall where exhibitors introduce "featured" products.

This month, RIKEN KEIKI NARA displayed a wide variety of devices to help deal with double shots or small dents during the stamping process.

RIKEN KEIKI NARA Mfg.CO., LTD. https://www.m-osaka.com/en/exhibitors/353/

L) Displayed devices

R) Examples of slug (scrap fragments)

【Proprietary sensor-equipped product line】

*Load monitoring device: Detects the force of die overlapping top and bottom to prevent damage to dies and stamping machines. Introduv\ced new models equipped with breakthrough confirmation function.

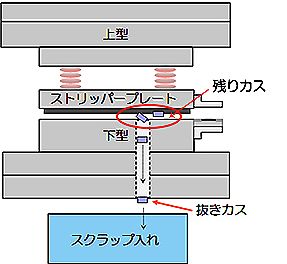

*Slug (Scrap) detector: Able to simultaneously monitor slug inside die and die height variation. Ideal for improving product accuracy.

*Error Detector: Detect miss feed and output errors for die protection.

*Multi-counter: Count production by general-purpose total count, preset and N-cut functions.

For a detailed explanation of "add a definite reliability to press work", watch this video.

Please visit the MOBIO Tech Hall to see the latest technologies of new exhibitors. Click here for a list of exhibitors.